The benchlearning focuses on the Design Factory (DF).

Design Factories implemented in other UASs were chosen as target groups. Discussion was started with two potential partner organisations, which were similar in the size of the staff and whose DFs had been established relatively recently. The Porto Design Factory was established in 2015 at Porto Polytechnic in Portugal and the inno.space Design Factory Mannheim was established in 2018 at Hochschule Mannheim in Germany. To gain a better understanding of the partners a visit to the Porto Design Factory was organised and the planning of a joint course with the inno.space Design Factory Mannheim was started.

The planning with the inno.space Design Factory Mannheim resulted in a joint course titled the International Product Development Project, which was organised from 16th March to 6th July 2021. The course included weekly co-teaching and co-planning together with the inno.space DF Mannheim. Based on these experiences inno.space DF Mannheim was selected as the partner organisation as both parties identified good practices that could be learned from each other.

HAMK’s objectives included to learn:

- good practices for organising international courses with other design factories

- about hosting and facilitating international Design Factory Global Network (DFGN) events and activities

- how to partner and organise university-industry collaboration with international companies and organisations

- about the SUGAR network and how HAMK could participate in the network and in ME310—a 9-month-long master’s level programme on global innovation that inno.space Design Factory Mannheim started in 2014 in collaboration with Stanford University.

Inno.space DF Mannheim’s objective was to learn about how to scale student projects to involve larger numbers of students in their DF courses and workshops.

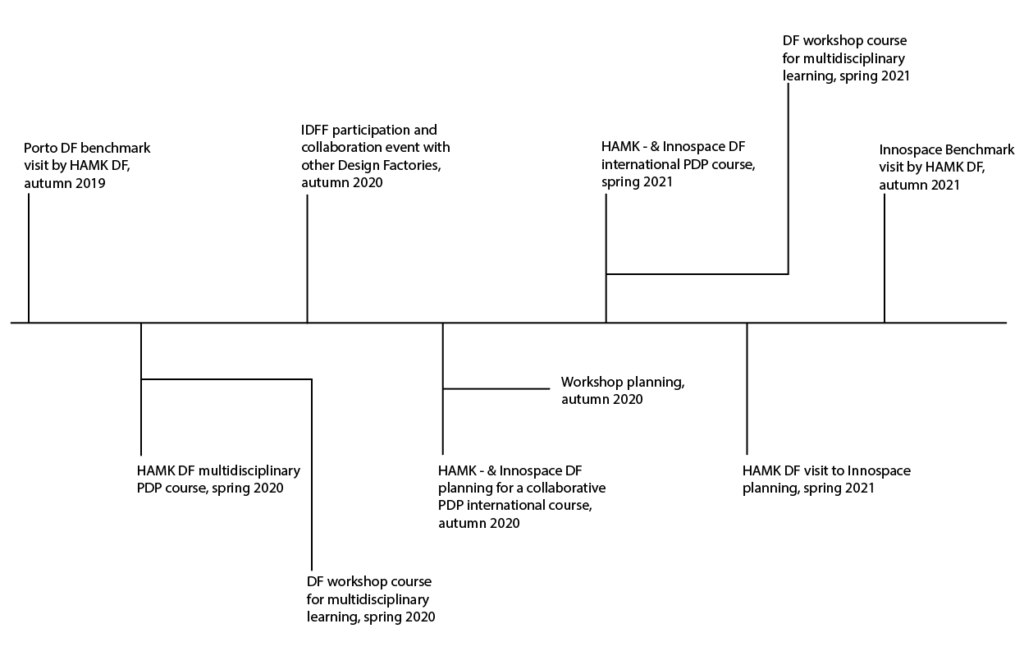

The benchlearning was implemented by: 1) physical visits, 2) joint teaching and learning, 3) online meetings, and 4) workshops. Physical visits included observations and interviews with DF personnel and some joint teaching and learning activities. For example, HAMK DF staff participated in the teaching of an international bootcamp organised by inno.space DF Mannheim.

In addition to visits, inno.space Design Factory Mannheim followed the planning and implementation of a multidisciplinary product development project organised by the HAMK DF. Also a joint planning and implementation of an international product development project involving students from both UASs took place. Online meetings were organised to plan and implement the teaching activities and to facilitate benchlearning visits.

The first activity was a benchlearning visit to Porto Design Factory by Senior Lecturer Ville Siipola and Senior Lecturer Jaakko Vasko from HAMK.

Discussions with inno.space Design Factory Mannheim resulted, first, in inno.space DF Mannheim staff following the launch of the HAMK DF multidisciplinary PDP course by participating in Zoom teaching sessions. In the International Design Factory Festival it was agreed that the HAMK DF and inno.space DF Mannheim would together organise an international product development project to deepen their collaboration. This course took place fully online during the Covid-19 lockdown. Co-teaching was planned and implemented using Slack, Google Drive, Zoom, and Mural platforms.

When the physical lockdowns were removed, a benchlearning visit to inno.space DF Mannheim was organised. Participants in the benchlearning visit included Technical Specialist Markku Mikkonen and Marketing Assistant Jali Närhi from HAMK, and Teaching Team Member Clara Dieing, Teaching Team Member Damien Wrobel, Prototyping and Workshop Assistant Manuel Walter, Professor Peter Kaiser and coordinator Professor Kirstin Kohler from inno.space DF Mannheim.

The implementation of the benchlearning process was successful. Observations from the visits to the Porto DF and inno.space DF uncovered answers to important questions set beforehand, but also revealed some surprising findings. The challenges of attracting students to join the DFGN and SUGAR projects in the Porto DF and inno.space DF were a surprise for HAMK staff considering that they both have a longer history of successful projects. It turned out that the inno.space DF Mannheim cannot award credits independently, which necessitates conforming to what has been agreed with particular Mannheim degree programmes. Furthermore, the inno.space DF Mannheim was unable to award credits for their workshops, which in practice meant that they are extra work for the students. Even with these limitations, inno.space DF Mannheim has been successful in launching several joint international courses with other design factories.

In HAMK one central limitation was observed to be the participation of master’s-level students in the DF courses. International courses organised by the Design Factory Global and SUGAR networks typically necessitate intensive and regular interaction between international and interdisciplinary student groups from different institutions. HAMK master’s degrees are, however, organised in the fashion that lessons take place on Friday evenings and Saturdays so that it is possible to study alongside a job. Whereas, international courses typically require travel between different international locations during the working week and can also include several days or a week-long bootcamp event for students limiting potential master’s level participants from Finland.

The jointly organised international product development project was able to demonstrate that HAMK bachelor’s level students and Mannheim master’s level students were able to successfully complete an international product development project for Coffee Consulate in Germany, and despite the difference in study levels, HAMK students were capable of meeting the requirements set for the students participating in Design Factory Global Network projects. Based on these experiences, it was decided to continue the international product development project also in future years.

| Good practices of HAMK | Good practices of the partner organisation |

| Close collaboration with degree programmes and research units. | Extensive teaching collaboration with other design factories, e.g. Aalto Design Factory and Tarto Sandbox |

| Jointly organised studies that are included in the curriculum of the following HAMK degree programmes: Sustainable and Smart Design, Bioeconomy Engineering and Sustainable Development, and the HAMK Design Factory offering. | Actively hosting and facilitating DFGN events including the International Design Factory Week and International Design Factory Festival activities. |

| Provides the possibility for anyone to do low, medium and high fidelity prototyping in HAMK DF spaces, with tools, materials and other equipment. | Member of SUGAR network (since 2014), which provides the M310 course in common yearly with the content to be shared between other SUGAR Universities. |

| Students are awarded credits for participating in Design Factory courses and workshops by Design Factory. | Provides the possibility for anyone to do low and medium fidelity prototyping with their space, tools, materials and other equipment. |

| Students need to apply for DFGN, and SUGAR network project and applicants are interviewed. |

| Applied good practices of the benchlearning partner |

| The most concrete examples of applying new ideas include the already-established international product development project with inno.space DF Mannheim.

Another concrete example to strengthen the international and global collaboration with other HEIs is a student project proposal submitted to ATTRACT phase 2 Developing breakthrough technologies for science and society together with inno.space DF Mannheim and Aalto Design Factory. Benchlearning also resulted in better understanding of prototyping machinery and approaches that can be implemented in the future investment rounds to provide a lower threshold for students to participate in prototyping at HAMK Design Factory. |

Audit team’s feedback

Design Factory was also HAMK’s benchlearning area, as HAMK did not only want to compare its Design Factory approach to others but at the same time learn from others on how to strengthen the impact of DF projects and experimental learning on teaching and learning. The partners were selected among other UASs who also had established a Design Factory recently. The partners were The Porto Design Factory and inno.space Design Factory Mannheim, both very active and innovative in this field.

The objective for the benchlearning project was to learn good practices for 1) organising international courses, 2) facilitating international DF Global Network activities, 3) learning how to establish university-industry collaboration with international companies and 4) learning more about the SUGAR network, its goals and objectives and also to participate in the network. It was implemented by site-visits, joint courses, online meetings and workshops. The HAMK’s concept aims at using the Design Factory as a method in which participants learn from each other in relation to a given topic, identify commonalities and differences, and work out good practices. Hence, the goals of benchlearning were clearly set and the process was carried out systematically during 2019-2021.

During the process, HAMK has learned many good practices, options for improvement were identified and new ideas as to further developing the use of HAMK’s Design Factory were gained. One concrete example was to have acquired a better understanding of the prototyping machinery and of approaches that can be implemented in the future investment rounds such as a lower threshold for students to participate in prototyping at the HAMK Design Factory. This means that the focus of benchlearning was on joint learning and the joint creation of content (co-creation) rather than on quantitative comparison (figures, data, facts). HAMK is encouraged to continue the well-established cooperation with international network projects and further develop and expand Design Factory activities.